I-RPET Pallets I-Crystallization Dryer

I-PET Infrared crystallization Dryer yama-R-PET Pellets ----OD Ubuchwepheshe Benziwe

>> Dry &Crystallize PET Chips/Flake/Pellets in 20mins at 30ppm ngokonga 45-50% wezindleko zamandla.

- Ukusetshenziswa kwamandla okungafika ku-60% kunesistimu yokomisa evamile

- I-crystallization efanayo

- Awekho ama-pellets ahlanganayo nokunamathela

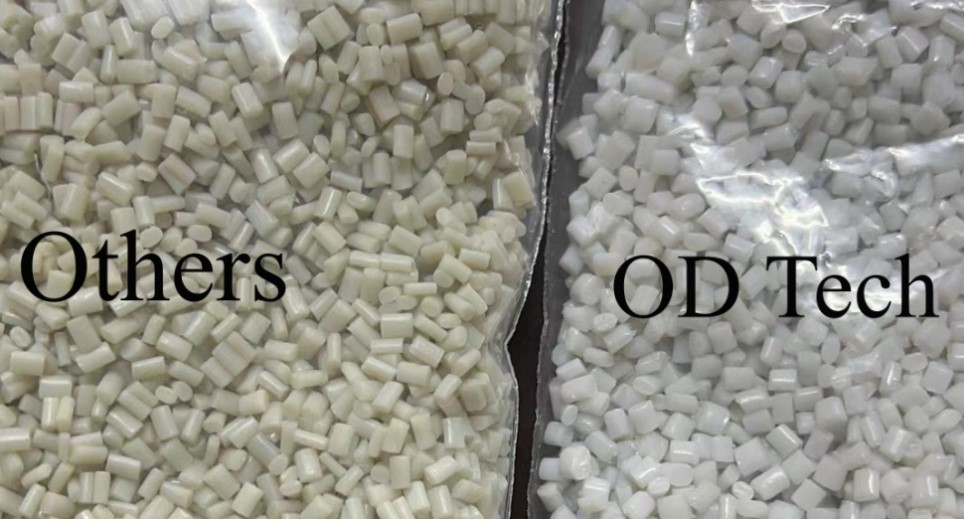

- Umbala we-Crystallization Ubisi olumhlophe

- Ukwelashwa ngezinto ezibonakalayo ngokucophelela

- Ukuqalisa okusheshayo nokuvala shaqa ngokushesha

- Izinga lokushisa elizimele kanye nesikhathi sokumisa simisiwe

- Akukho ukuhlukaniswa kwemikhiqizo enokuminyana kwenqwaba ehlukene

- Ukuhlanza okulula nokushintsha impahla

Ungakhuphula kanjani inani elengeziwe lomkhiqizo lama-R-PET Pellets/ PET Pellets enziwe i-Bottle flake byIsomisi se-infrared crystallization?

| 1 | crystallization Uniform, okusezingeni eliphezulu crystallization rate Umbala we-Crystallization: omhlophe qwa

|

Intengo yokuthengisa izoba ngu-USD30-50 Ngethani

|

| 2 | I-Crystallization kanye nokoma kuzoqedwa ngesinyathelo esisodwa Umswakama wokugcina ungaba ≤50ppm | Kuzoba iphuzu elihle kumsebenzisi olandelayo, njengomkhiqizi we-PET Preform, ukwakhiwa kwe-PET Sheet noma ukukhiqizwa kwe-Fiber njll. Kuzofinyeza isikhathi sabo sangaphambi kokoma. |

| 3 | Umshini ophelele olawulwa isikrini sokuthinta se-Siemens PLC esinomsebenzi wenkumbulo, isiqalo esibalulekile esisodwa. | Ukunciphisa izindleko zabasebenzi besu. |

| 4 | Yonga cishe u-45-50% wezindleko zamandla uma uqhathaniswa nesomiso se-Dessicant | Thatha imodeli ye-infrared crystal dryer engu-500kg/h njengesibonelo, izindleko zikagesi zingaphansi kuka-100W/KG/HR |

Yini esingakwenzela yona

>> Nciphisa ukucekelwa phansi kwe-hydrolysis kwe-viscosity.

>>Vimbela ukukhuphuka kwamazinga e-AA ezintweni ezithintana nokudla

>> Ukwandisa amandla omugqa wokukhiqiza aze afike ku-50%

>>Thuthukisa futhi wenze ikhwalithi yomkhiqizo izinze-- Okuqukethwe komswakamo olinganayo nokuphindaphindwayo

>>Kunezindawo ezintathu zokulawula izinga lokushisa le-PID, futhi izinga lokushisa lokumisa ikristalu lingasethwa ngokuvumelana nezici zezinto zokusetshenziswa.

>> Isitayela sokusebenza esijikelezayo singasebenza njengesixube. Ungakwazi ukuphakela iphesenti le-PET Chips nama-pellets agaywe kabusha esomisweni sethu se-Infrared crystal ngqo, sizoxuba izinto ngokuzenzakalelayo.

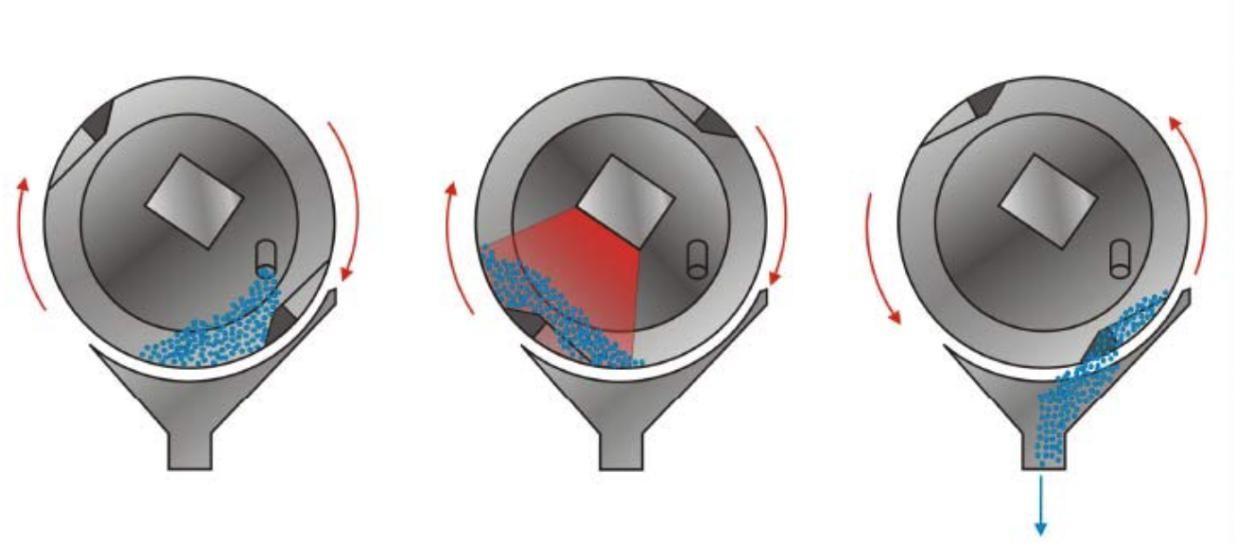

Indlela yokusebenza

Iyaphakela/iyalayisha

Okomisa & Crystallization Processing

Iyakhipha

>>Esinyathelweni sokuqala, okuwukuphela kwethagethi ukushisisa okokusebenza kumazinga okushisa asethiwe.

Yamukela isivinini esihamba kancane sokuzungezisa isigubhu, amandla amalambu e-Infrared esomisa azoba sezingeni eliphezulu, bese kuthi ama-PET pellets abe nokushisisa okusheshayo kuze kube yilapho izinga lokushisa likhuphuka liye ezingeni lokushisa elisethiwe.

>>Ukomisa &isinyathelo sokucwebezela

Uma impahla ifika emazingeni okushisa, isivinini sesigubhu sizokwenyuswa siye kwisivinini esiphezulu kakhulu sokuzungeza ukuze kugwenywe ukunqwabelana kwezinto. Ngesikhathi esifanayo, amandla amalambu e-infrared azokwengezwa futhi ukuze aqedele ukomisa. Khona-ke isivinini sokuzungeza isigubhu sizoncishiswa futhi. Ngokuvamile inqubo yokomisa izoqedwa ngemva kwemizuzu engu-15-20. (Isikhathi esiqondile sincike endaweni yezinto)

>>Ngemva kokuqeda ukucutshungulwa kokumisa, i-IR Drum izokhipha ngokuzenzakalelayo okokusebenza futhi igcwalise kabusha isigubhu emjikelezweni olandelayo.

Ukugcwaliswa kabusha okuzenzakalelayo kanye nawo wonke amapharamitha afanelekile wamarempu okushisa ahlukene ahlanganiswe ngokugcwele kusilawuli sesimanjemanje se-Touch Screen. Uma amapharamitha namaphrofayili wokushisa esetholelwe into ethile, izilungiselelo zethisthi zingalondolozwa njengamaresiphi ohlelweni lokulawula.

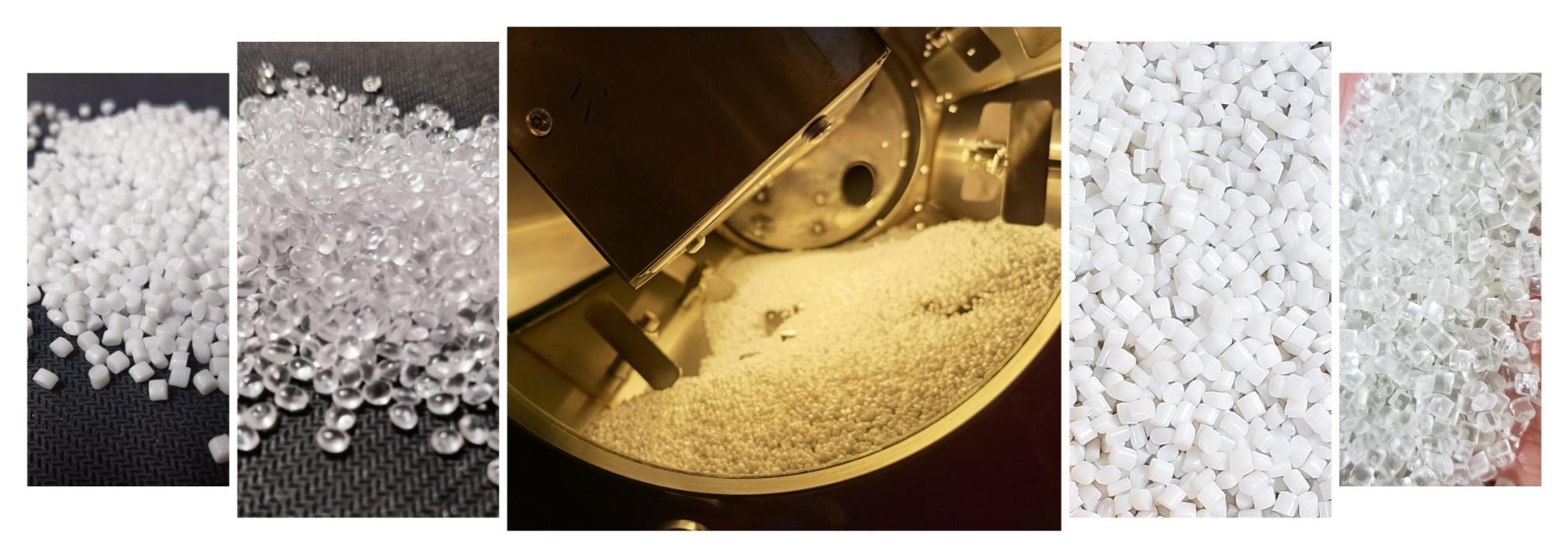

Izithombe zomshini ukuze zisetshenziswe

Ukuhlola kwamahhala okubalulekile

Unjiniyela onolwazi uzokwenza ukuhlolwa. Abasebenzi bakho bamenywa ngokufudumele ukuthi babambe iqhaza emizileni yethu ehlanganyelwe. Ngakho unakho kokubili ithuba lokunikela ngenkuthalo kanye nethuba lokubona imikhiqizo yethu isebenza.

>> Nikeza unjiniyela onolwazi efekthrini yakho ukusiza ukufakwa kanye nokuhlolwa kwempahla kusebenza

>> Yamukela ipulaki yendiza, asikho isidingo sokuxhuma izintambo zikagesi kuyilapho ikhasimende lithola umshini efektri yalo. Ukwenza lula isinyathelo sokufaka

>> Nikeza ividiyo yokusebenza ukuze ifakwe kanye nomhlahlandlela osebenzayo

>> Ukwesekwa on line service