I-PLA PET thermoforming Sheet extrusion line

I-infrared crystal dryer+ ulayini we-PET Sheet Extrusion

Inzuzo esiyenzayo

>> U-LIANDA uthuthukisa iUmugqa wokukhipha isikulufu esisodwa esomisa ngekristalu ye-infraredkushidi le-PET, i-20mins pre-drying and crystallization, umswakama wokugcina ungaba ≤50ppm (Umugqa womshini Sebenza ngokuzinzile, ikhwalithi yokugcina yeshidi izinzile)

I-extrusion line inezindawo zokusetshenziswa kwamandla aphansi, inqubo yokukhiqiza elula kanye nokugcinwa okulula.

Isakhiwo sesikulufu esihlukaniswe izingxenye singanciphisa ukulahleka kwe-viscosity ye-PET resin, i-symmetrical and thin-wall calender roll ithuthukisa umphumela wokupholisa, umthamo kanye nekhwalithi yeshidi.

Isiphakeli somthamo wezingxenye eziningi silawula iphesenti lento entsha, izinto ezigaywe kabusha kanye neqoqo eliyinhloko ngokunembile,.

Ishidi lisetshenziswe kabanzi embonini yokupakisha ye-thermoforming.

>>Isomisi sekristalu esingabonakali -----Dry &Crystallize R-PET flakes/chips in 20mins at 30ppm ngokonga 45-50% wezindleko zamandla.

※Ukunciphisa ukuwohloka kwe-hydrolytic ye-viscosity.

※ Vimbela ukukhuphuka kwamazinga e-AA ezintweni ezithinta ukudla

※ Ukwandisa amandla omugqa wokukhiqiza aze afike ku-50%

※ Thuthukisa futhi wenze ikhwalithi yomkhiqizo izinze-- Okuqukethwe komswakamo olinganayo nokuphindaphindwayo wento

Yehlisa izindleko zokwenziwa kweshidi le-PET: Kufika ku-60% ukusetshenziswa kwamandla angaphansi kunesistimu yokomisa evamile

Ukuqalisa okusheshayo nokuvala shaqa ngokushesha --- Asikho isidingo sokushisisa kwangaphambili

Ukomisa nokucwengeka kuzocutshungulwa ngesinyathelo esisodwa

Ukuze uthuthukise amandla okuqina weshidi le-PET, Khulisa inani elingeziwe--- Umswakama wokugcina ungaba ≤30ppm nge-20minsUkomisa & Crystallization

- Ulayini womshini ufakwe uhlelo lwe-Siemens PLC nomsebenzi owodwa obalulekile wenkumbulo

- Ihlanganisa indawo yesakhiwo esincane, esilula futhi kulula ukuyisebenzisa nokugcinwa

- Izinga lokushisa elizimele kanye nesikhathi sokumisa simisiwe

- Akukho ukuhlukaniswa kwemikhiqizo enokuminyana kwenqwaba ehlukene

- Ukuhlanza okulula nokushintsha impahla

>> PET Extrusion machine line

| Imodeli | Isendlalelo esiningi | Isendlalelo esisodwa | Isebenza kahle kakhulu |

| Ukucaciswa kwe-Extruder | LD75&36/40-1000 | LD75/40-1000 | LD95&62/44-1500 |

| Ubukhulu bomkhiqizo | 0.15-1.5mm | 0.15-1.5mm | 0.15-1.5mm |

| Amandla emoto amakhulu | 110kw/45kw | 110kw | 250kw/55kw |

| Umthamo omkhulu we-extrusion | 500kg/h | 450kg/h | 800-1000kg/h |

Uhlu lomshini

| Ukwakhiwa Komshini | ||

| NO | Umshini | Ubuningi |

| 1 | I-PET infrared crystal dryer | 1 isethi |

| 2 | I-vacuum screw feeder | 1 isethi |

| 3 | Isikulufa esiphindwe kabili | 1 isethi |

| 4 | Vacuum isistimu yengcindezi engalungile | 1 isethi |

| 5 | Isihlungi sesiteshi esikabili | 1 isethi |

| 6 | Ncibilikisa iphampu yemitha | 1 isethi |

| 7 | Isikhunta esikhethekile se-PET siyafa | 1 isethi |

| 8 | Ingxenye yokwenza i-Calendering yamaroll amathathu | 1 isethi |

| 9 | I-Silicone oil coating kanye nedivayisi ye-Oven | 1 isethi |

| 10 | Idivayisi yokusika impahla ye-Edge | 1 isethi |

| 11 | Idivayisi yokutholwa kwe-Edge | 1 isethi |

| 12 | Isistimu yokumaya eziteshini ezimbili | 1 isethi |

| 13 | SIEMENS uhlelo lokulawula isixhumi esibonakalayo somshini womuntu | 1 isethi |

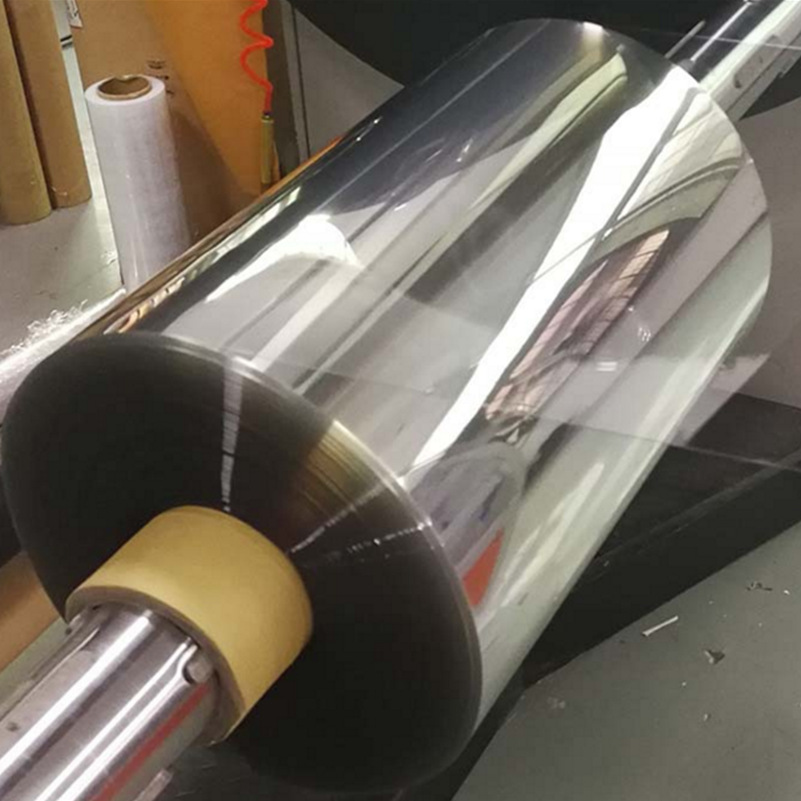

Izithombe Zomshini

FAQ

Q: Yimuphi umswakamo wokugcina ongawuthola? Ingabe unomkhawuko kumswakama wokuqala wempahla eluhlaza?

A: Umswakama wokugcina esingawuthola ≤30ppm (Thatha i-PET njengesibonelo). Umswakama wokuqala ungaba ngu-6000-15000ppm.

Q: Sisebenzisa i-Double parallel screw extruding nge-vacuum degassing system ye-PET Sheet extrusion, ingabe sisazodinga ukusebenzisa okomisa kuqala?

A: Siphakamisa ukuthi usebenzise Isomisi sangaphambili ngaphambi kwe-extrusion. Imvamisa uhlelo olunjalo lunesidingo esiqinile kumswakama wokuqala we-PET material. Njengoba sazi ukuthi i-PET iwuhlobo lwezinto ezikwazi ukumunca umswakama ovela emkhathini okuzokwenza ukuthi ulayini we-extrusion usebenze kabi. Ngakho-ke siphakamisa ukuthi usebenzise isomisi sangaphambili ngaphambi kwesistimu yakho ye-extrusion:

>> Ukunciphisa ukucekelwa phansi kwe-hydrolytic kwe-viscosity

>>Vimbela ukukhuphuka kwamazinga e-AA ezintweni ezithinta ukudla

>> Ukwandisa amandla omugqa wokukhiqiza aze afike ku-50%

>>Thuthukisa futhi wenze ikhwalithi yomkhiqizo izinze-- Okuqukethwe komswakamo olinganayo nokuphindaphindwayo wento

UMB: Sizosebenzisa izinto ezintsha kodwa asinaso isipiliyoni sokumisa izinto ezinjalo. Ungasisiza?

A: Imboni yethu ineSikhungo Sokuhlola. Esikhungweni sethu sokuhlola, singenza izivivinyo eziqhubekayo noma ezingaqhubeki zesampula yezinto zekhasimende. Imishini yethu inikezwe ubuchwepheshe obuphelele bokuzenzakalela kanye nokulinganisa.

Singakhombisa --- Ukudlulisa/Ukulayisha, Ukomisa & I-Crystallization, Ukukhipha.

Ukomiswa kanye nekristalu yezinto ezibonakalayo ukunquma umswakama osele, isikhathi sokuhlala, okokufaka kwamandla kanye nezakhiwo ezibonakalayo.

Futhi singabonisa ukusebenza ngokuthola inkontileka engaphansi kwamaqoqo amancane.

Ngokuhambisana nezidingo zakho zempahla nokukhiqiza, singakwazi ukuhlela uhlelo nawe.

Unjiniyela onolwazi uzokwenza ukuhlolwa. Abasebenzi bakho bamenywa ngokufudumele ukuthi babambe iqhaza emizileni yethu ehlanganyelwe. Ngakho unakho kokubili ithuba lokunikela ngenkuthalo kanye nethuba lokubona imikhiqizo yethu isebenza.

Q: Yisiphi isikhathi sokulethwa kwe-IRD yakho?

A: Izinsuku zokusebenza ezingama-40 kusukela sithole idiphozithi yakho ku-akhawunti yenkampani yethu.

Q: Kuthiwani ngokufakwa kwe-IRD yakho?

Unjiniyela onolwazi angasiza ukukufakela isistimu ye-IRD efekthri yakho. Noma singanikeza isevisi yomhlahlandlela kulayini. Umshini wonke usebenzisa ipulaki yendiza, kulula ukuxhuma.

Q: Ithini i-IRD engafakelwa yona?

A: Kungaba pre-dryer for

Ulayini womshini wokukhipha i-PET/PLA/TPE Sheet

Umugqa womshini wokwenza ibhande le-PET Bale

I-PET masterbatch crystallization nokomisa

I-PETG Sheet extrusion line

Umshini we-PET monofilament, umugqa we-PET monofilament extrusion, i-PET monofilament yomshanelo

I-PLA/PET Umshini wokwenza ifilimu

I-PBT, i-ABS/PC, i-HDPE, i-LCP, i-PC, i-PP, i-PVB, i-WPC, i-TPE, i-TPU, i-PET (ama-Bottleflakes, ama-granules, ama-flakes), i-PET masterbatch, i-CO-PET, i-PBT, i-PEEK, i-PLA, i-PBAT, i-PPS njll.

Izinqubo ezishisayo ze-ukususwa kwe-oligomeren yokuphumula kanye nezingxenye eziguquguqukayo.