I-PET Granulating line

I-Infrared Crystallization Dryer yomugqa we-rPET Extrusion granulating

I-Infrared Pre-Drying ye-rPET Bottle Flakes: Ukwandisa Okukhiphayo kanye Nokuthuthukisa Ikhwalithi Kuma-PET Extruder

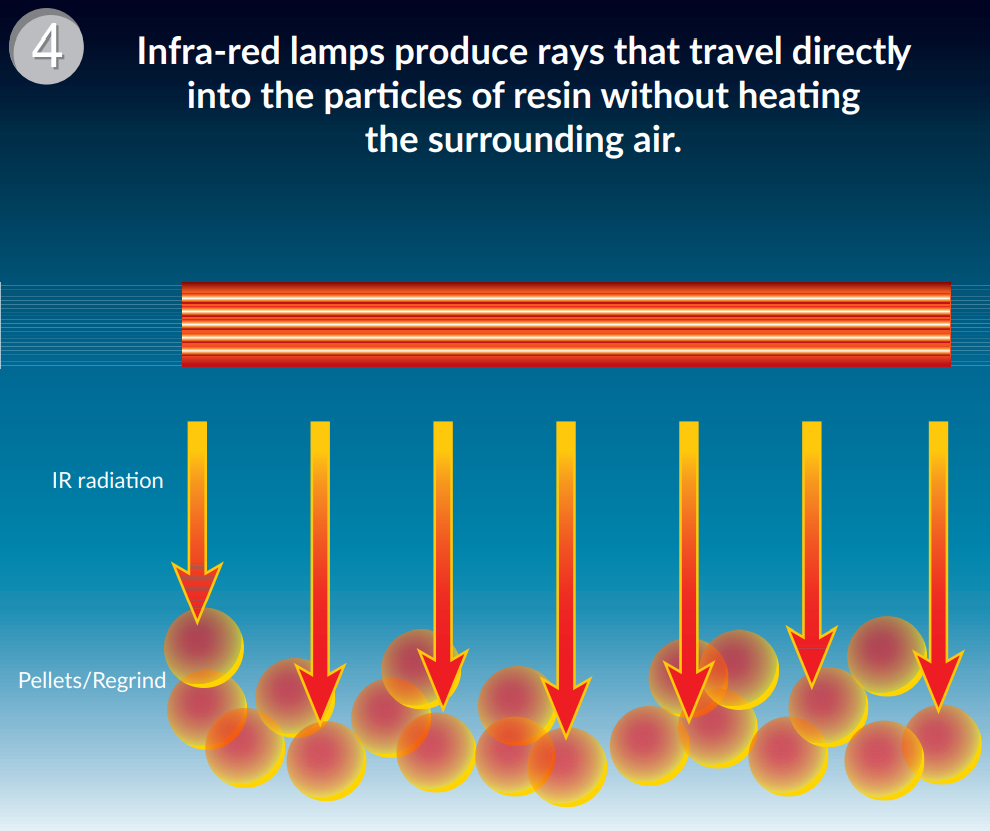

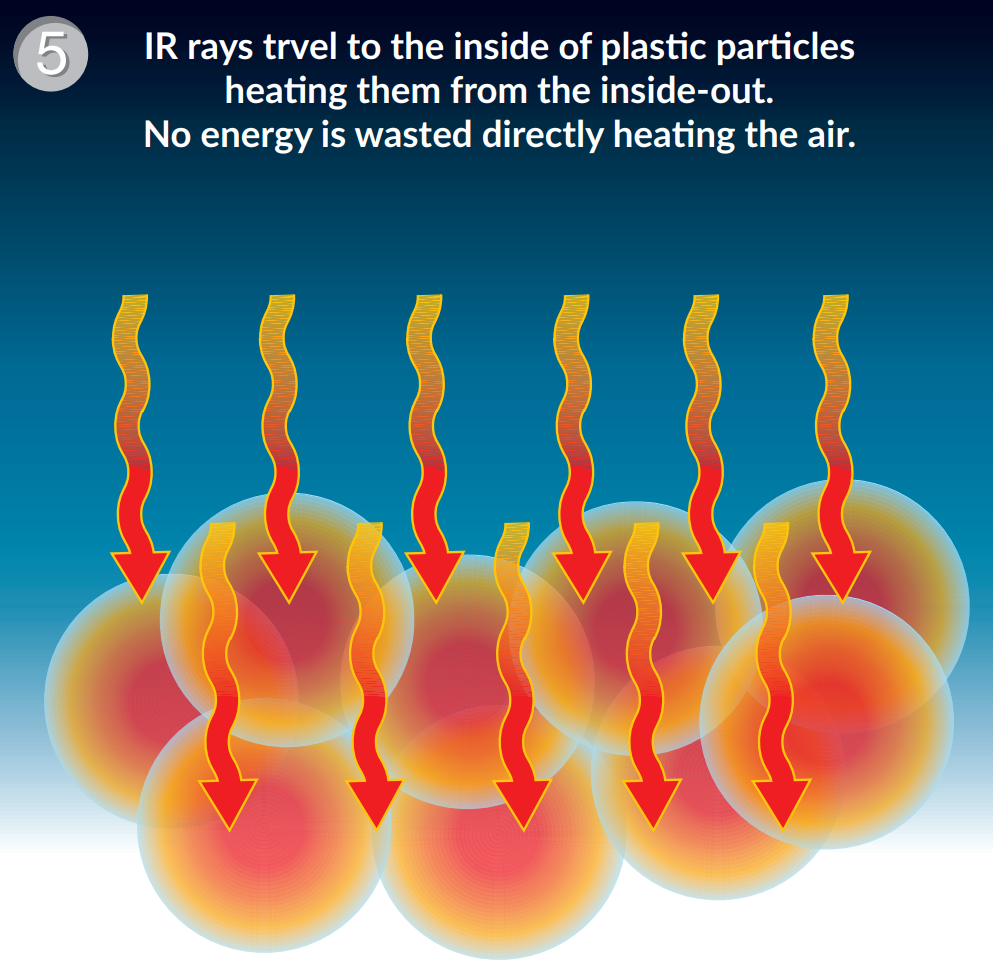

Ukomisa kuwukuguquguquka okukodwa okubaluleke kakhulu ekucubunguleni.

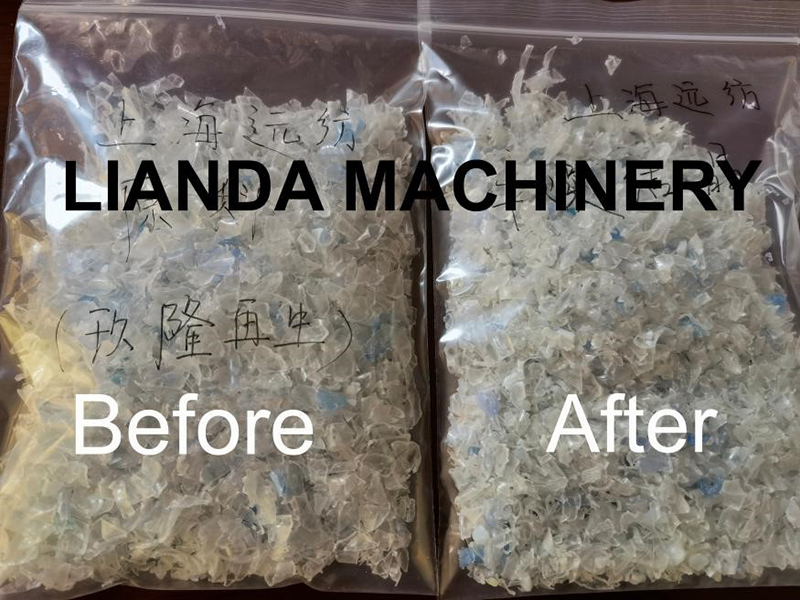

>> Ukuthuthukisa ukukhiqizwa kanye nezakhiwo ezibonakalayo ze-PET egaywe kabusha, yebanga lokudla ngobuchwepheshe obunikwa ukukhanya kwe-infrared kunengxenye ebalulekile okufanele iyidlale endaweni ye-intrinsic viscosity (IV)

>>I-pre-crystallization & ukomiswa kwama-flakes ngaphambi kokukhishwa kusiza ukunciphisa ukulahlekelwa kwe-IV ku-PET, isici esibalulekile sokuphinda kusetshenziswe inhlaka.

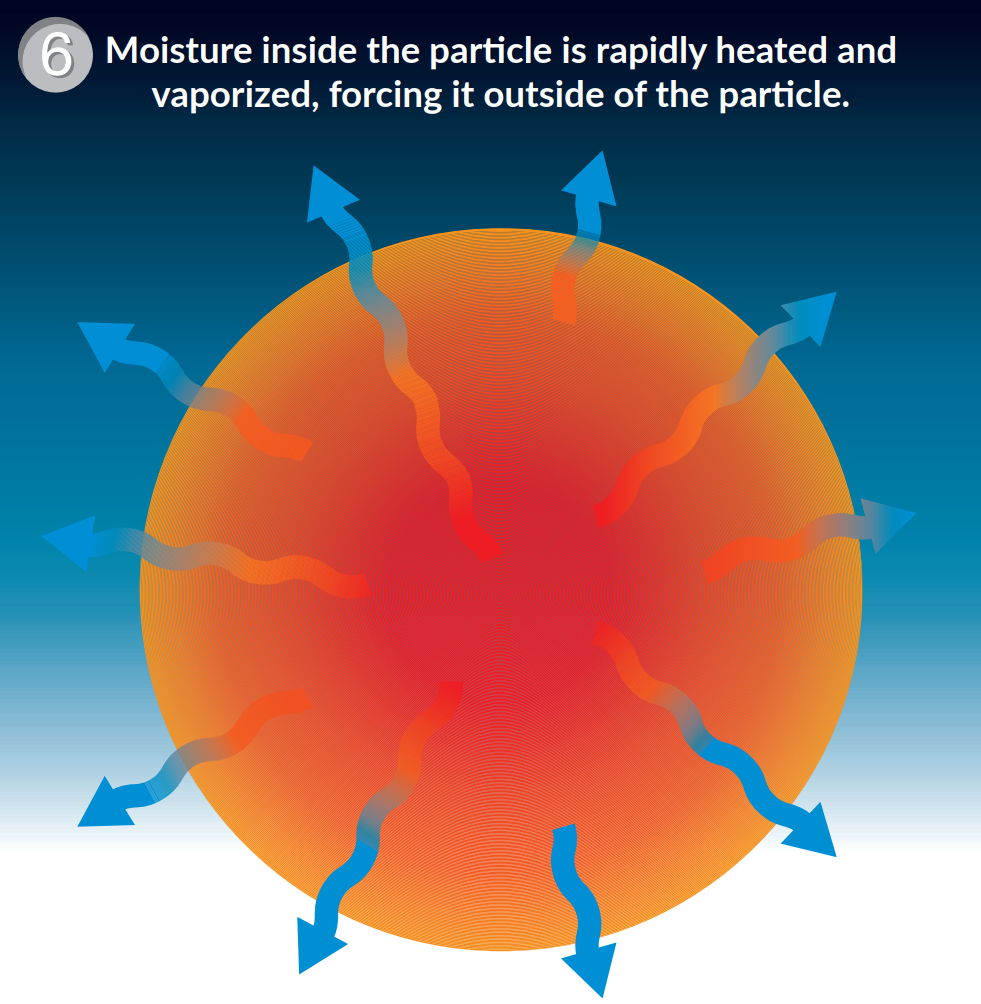

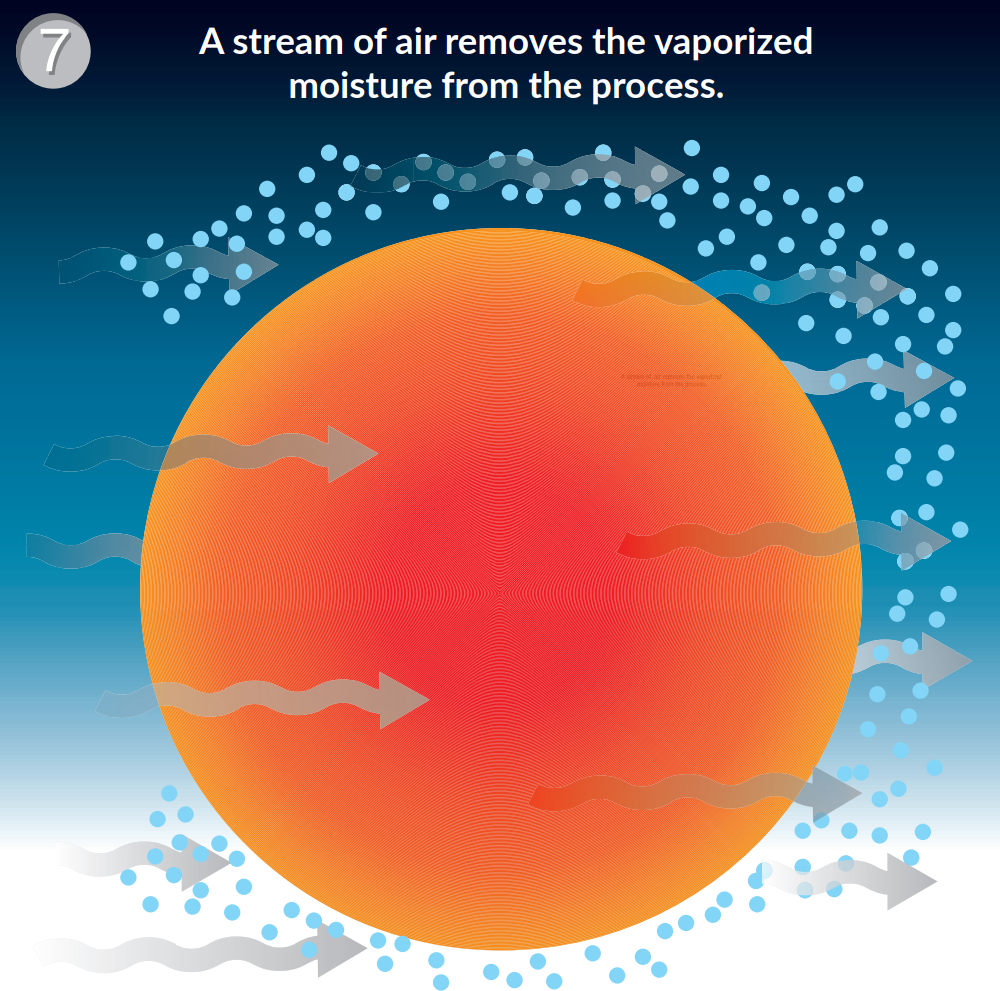

>>Ukucutshungulwa kabusha ama-flakes ku-extruder kunciphisa i-IV ngenxa ye-hydrolysis i ukuba khona kwamanzi, futhi yingakho ukomisa kusengaphambili kuze kube sezingeni lokumisa okulinganayo ngoHlelo lwethu lwe-IRD kungakhawulela lokhu kuncipha. Ngaphezu kwalokho,i-PET melt strips ayiphuzi ngoba isikhathi sokumisa sincishisiwe( Isikhathi sokumisa sidinga kuphela i-15-20mins, umswakama wokugcina ungaba ≤ 30ppm, ukusetshenziswa kwamandla ngaphansi kuka-80W/KG/H)

>>Ukugunda ku-extruder nakho kuyancishiswa ngoba impahla eshisiwe ingena ku-extruder ngokushisa okungashintshiyo”

>> Ukwenza ngcono ukuphuma kwe-PET Extruder

Ukwenyuka kokuminyana kwenqwaba ngo-10 kuya ku-20 % kungafinyelelwa ku-IRD, kuthuthukisa ukusebenza kokuphakelayo endaweni yokufaka i-extruder kakhulu - kuyilapho isivinini se-extruder sihlala singashintshile, kunokusebenza kokugcwalisa okuthuthuke kakhulu kusikulufu.

Isimiso Sokusebenza

I-Advantage Siyayenza

※Ukunciphisa ukuwohloka kwe-hydrolytic ye-viscosity.

※ Vimbela ukukhuphuka kwamazinga e-AA ezintweni ezithinta ukudla

※ Ukwandisa amandla omugqa wokukhiqiza aze afike ku-50%

※ Thuthukisa futhi wenze ikhwalithi yomkhiqizo izinze-- Okuqukethwe komswakamo olinganayo nokuphindaphindwayo wento

→ Yehlisa izindleko zokwenziwa kwama-PET pellets: Kufika ku-60% ukusetshenziswa kwamandla angaphansi kunesistimu yokomisa evamile

→ Ukuqalisa okusheshayo nokuvala shaqa ngokushesha --- Asikho isidingo sokushisisa kwangaphambili

→ Ukomisa nokucwebezela kuzocutshungulwa esinyathelweni esisodwa

→ Ulayini womshini ufakwe isistimu ye-Siemens PLC enokhiye owodwa wokukhumbula umsebenzi

→ Ihlanganisa indawo enesakhiwo esincane, esilula futhi kulula ukuyisebenzisa nokuyinakekela

→ Izinga lokushisa elizimele kanye nesikhathi sokumisa simisiwe

→ Akukho ukuhlukaniswa kwemikhiqizo enobuningi obuhlukahlukene

→ Ukuhlanza okulula nokushintsha impahla

Ukusebenza komshini efekthri yamakhasimende

FAQ

Q: Yimuphi umswakamo wokugcina ongawuthola? Ingabe unomkhawuko kumswakama wokuqala wempahla eluhlaza?

A: Umswakama wokugcina esingawuthola ≤30ppm (Thatha i-PET njengesibonelo). Umswakama wokuqala ungaba ngu-6000-15000ppm.

Q: Sisebenzisa i-Double parallel screw extruding nge-vacuum degassing system ye-PET Extrusion granulating line, ingabe sisazodinga ukusebenzisa isikomisi sangaphambili?

A: Siphakamisa ukuthi usebenzise Isomisi sangaphambili ngaphambi kwe-extrusion. Imvamisa uhlelo olunjalo lunesidingo esiqinile kumswakama wokuqala we-PET material. Njengoba sazi ukuthi i-PET iwuhlobo lwezinto ezikwazi ukumunca umswakama ovela emkhathini okuzokwenza ukuthi ulayini we-extrusion usebenze kabi. Ngakho-ke siphakamisa ukuthi usebenzise isomisi sangaphambili ngaphambi kwesistimu yakho ye-extrusion:

>> Ukunciphisa ukucekelwa phansi kwe-hydrolytic kwe-viscosity

>>Vimbela ukukhuphuka kwamazinga e-AA ezintweni ezithinta ukudla

>> Ukwandisa amandla omugqa wokukhiqiza aze afike ku-50%

>>Thuthukisa futhi wenze ikhwalithi yomkhiqizo izinze-- Okuqukethwe komswakamo olinganayo nokuphindaphindwayo wento

Q: Yisiphi isikhathi sokulethwa kwe-IRD yakho?

A: Izinsuku zokusebenza ezingama-40 kusukela sithole idiphozithi yakho ku-akhawunti yenkampani yethu.

Q: Kuthiwani ngokufakwa kwe-IRD yakho?

Unjiniyela onolwazi angasiza ukukufakela isistimu ye-IRD efekthri yakho. Noma singanikeza isevisi yomhlahlandlela kulayini. Umshini wonke usebenzisa ipulaki yendiza, kulula ukuxhuma.

Q: Ithini i-IRD engafakelwa yona?

A: Kungaba pre-dryer for

- Ulayini womshini wokukhipha i-PET/PLA/TPE Sheet

- Umugqa womshini wokwenza ibhande le-PET Bale

- I-PET masterbatch crystallization nokomisa

- I-PETG Sheet extrusion line

- Umshini we-PET monofilament, umugqa we-PET monofilament extrusion, i-PET monofilament yomshanelo

- I-PLA/PET Umshini wokwenza ifilimu

- I-PBT, i-ABS/PC, i-HDPE, i-LCP, i-PC, i-PP, i-PVB, i-WPC, i-TPE, i-TPU, i-PET (ama-Bottleflakes, ama-granules, ama-flakes), i-PET masterbatch, i-CO-PET, i-PBT, i-PEEK, i-PLA, i-PBAT, i-PPS njll.

- Izinqubo ezishisayo ze-ukususwa kwe-oligomeren yokuphumula kanye nezingxenye eziguquguqukayo.