I-PET Flake/i-scrap dehumidifier crystallizer

Isampula yohlelo lokusebenza

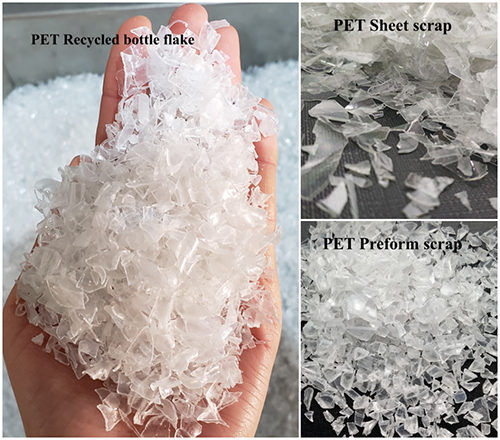

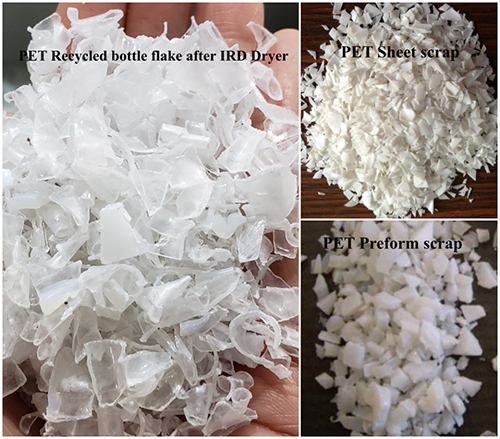

| Impahla eluhlaza | I-PET Recycled flake/ PET sheet scrap/PET Preform scrap |

|

| Ukusebenzisa Umshini | I-LDHW-600*1000 |  |

| Isethi Yokumisa Nokushisa Okucwebezelayo | I-180-200 ℃Ingalungiseka ngempahla ye-rawmaterial | |

| Isikhathi se-crystallized sisethiwe | 20 imiz | |

| Okokugcina | Izinsalela ze-PET ezicwebezelayo nezomisiwe kanyeumswakama wokugcina ungaba ngu-30ppm |  |

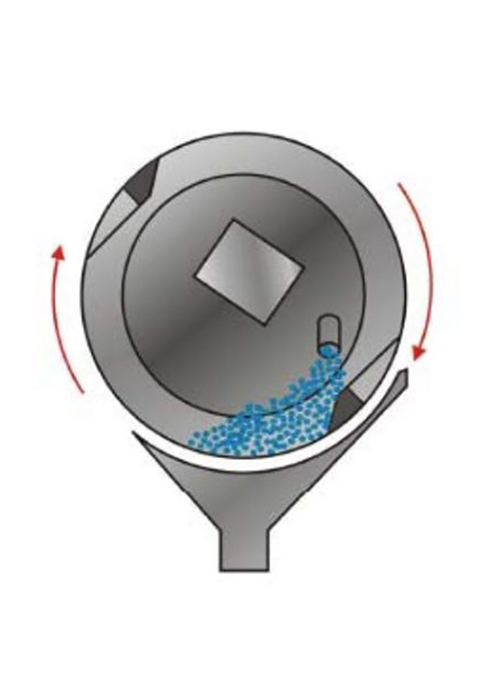

Indlela Yokusebenza

Iyaphakela/iyalayisha

Okomisa & Crystallization Processing

Iyakhipha

>>Esinyathelweni sokuqala, okuwukuphela kwethagethi ukushisisa okokusebenza kumazinga okushisa asethiwe.

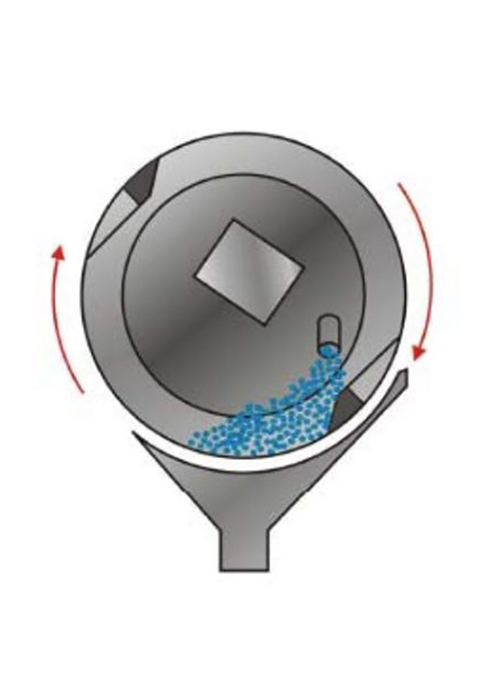

Yamukela isivinini esinensa kakhulu sokuzungezisa isigubhu, amandla amalambu e-Infrared esomisi azoba sezingeni eliphakeme, bese ama-PET pellets azoba nokushisisa okusheshayo kuze kube yilapho izinga lokushisa likhuphukela ezingeni lokushisa elisethiwe.

>>Ukomisa &isinyathelo sokucwebezela

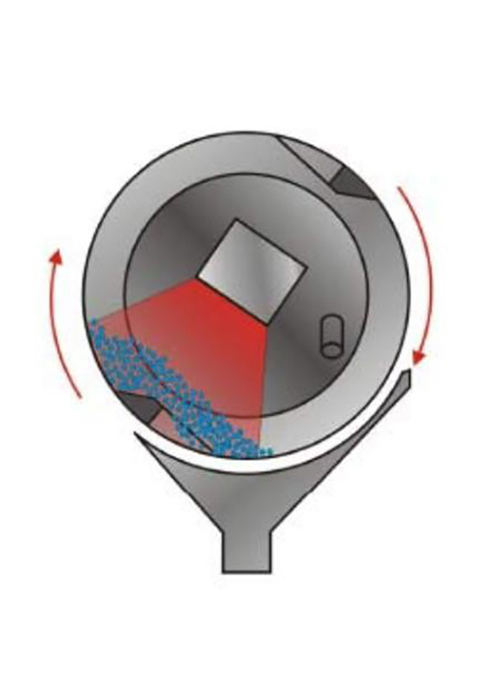

Uma impahla ifika emazingeni okushisa, isivinini sesigubhu sizokwenyuswa siye kwisivinini esiphezulu kakhulu sokuzungeza ukuze kugwenywe ukunqwabelana kwezinto. Ngesikhathi esifanayo, amandla amalambu e-infrared azokwengezwa futhi ukuze aqedele ukomisa. Khona-ke isivinini sokuzungeza isigubhu sizoncishiswa futhi. Ngokuvamile inqubo yokomisa izoqedwa ngemva kwemizuzu engu-15-20. (Isikhathi esiqondile sincike endaweni yezinto)

>>Ngemva kokuqeda ukucutshungulwa kokumisa, i-IR Drum izokhipha ngokuzenzakalelayo okokusebenza futhi igcwalise kabusha isigubhu emjikelezweni olandelayo.

Ukugcwaliswa kabusha okuzenzakalelayo kanye nawo wonke amapharamitha afanelekile wamarempu okushisa ahlukene ahlanganiswe ngokugcwele kusilawuli sesimanjemanje se-Touch Screen. Uma amapharamitha namaphrofayili wokushisa esetholelwe into ethile, izilungiselelo zethisthi zingalondolozwa njengamaresiphi ohlelweni lokulawula.

Inzuzo Yethu

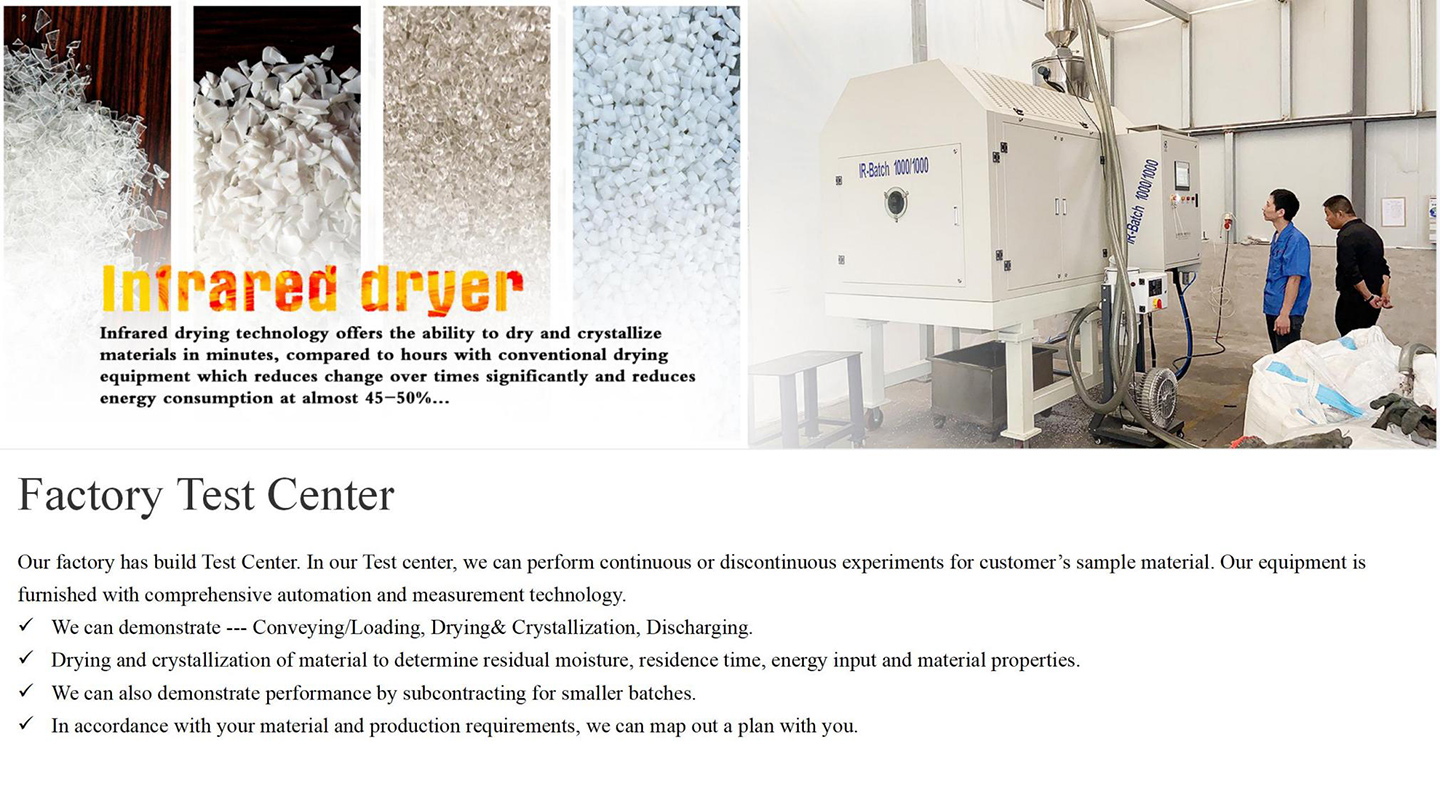

Ngokuvamile i-PET Bottle flakes noma izinsalela zeshidi ezinezinga lokuswakama lokuqala elifika ku-10000-13000ppm. I-PET Bottle flakes noma i-sheet scrap (i-Virgin noma exubile) izokwenziwa kabusha ku-Infrared crystal dryer in 20mins, izinga lokushisa lokoma lizoba ngu-150-180 ℃ futhi lomiswe libe ngu-50-70ppm, bese liphakelwa ohlelweni olulodwa lokukhipha isikulufu ukuze kuqhutshekwe nokucubungula.

● Ukunciphisa ukucekelwa phansi kwe-hydrolytic kwe-viscosity.

● Vimbela ukukhuphuka kwamazinga e-AA ezintweni ezithinta ukudla

● Ukwenyusa umthamo womugqa wokukhiqiza ufike ku-50%

● Thuthukisa futhi wenze ikhwalithi yomkhiqizo izinze-- Okuqukethwe komswakamo olinganayo nokuphindaphindwayo wento

● Ukusetshenziswa kwamandla okungafika ku-60% kunesistimu yokomisa evamile

● Akukho ukuhlukaniswa kwemikhiqizo enokuminyana kwenqwaba ehlukene

● Izinga lokushisa elizimele kanye nesikhathi sokumisa simisiwe

● Ukuhlanza kalula nokushintsha impahla

● Ukuqalisa okusheshayo nokuvala shaqa ngokushesha

● I-crystallization efanayo

● Awekho ama-pellets ahlanganisayo & stick

● Ukwelashwa ngokucophelela

Ithebula lokuqhathanisa

| Into | Isomisi se-IRD | Isomisi Esivamile |

| Dlulisa imidiya | Lutho | Umoya oshisayo |

| Ukudlulisa ukushisa | Kokubili izinhlayiya zangaphakathi nangaphandle ndawonye. | Ukusuka ngaphandle kuya ngaphakathi kuyizinhlayiyana kancane kancane. |

| Amandla | Yonga okungenani amandla angu-20 ~ 50% uma kuqhathaniswa nokomisa kwendabuko. | Sebenzisa amandla amaningi. |

| Isikhathi sokucubungula | 1. ICrystallization & drying: Acutshungulwa kanyekanye phakathi kwemizuzu eyi-8~15. 2. Ukomisa kanye crystallization ngesikhathi | 1. I-Crystallization: Cishe imizuzu engama-30 ~ 60. 2. Ukomisa: Cishe amahora angu-4–6. |

| Okuqukethwe umswakama | 1. Ngaphansi kuka-50-70 PPM ngemva kokucutshungulwa kwe-IRD. | 1. Chitha amaminithi angu-30~60 ukushintsha i-PET e-amorphous ibe yi-PET ecwebezelayo kuqala. 2. Ngaphansi kuka-200PPM ngemva cishe kwamahora angu-4 kucutshungulwe okokususa umswakama. 3. Ngaphansi kokungu-50 PPM ngemva cishe kwamahora angu-6 sekucutshungulwe okokukhipha umoya. |

| Isikhathi esiholayo | 20 imiz | Ngaphezu kwamahora angu-6. |

| Ukushintsha kwezinto | 1. Kulula futhi kuyashesha. 2. Kukhona amandla wezikhathi ezingu-1 ~ 1.5 kuphela zokusetshenziswa kwento yehora ku-bafa hopper. | 1. Kunzima & kancane. 2. Kukhona umthamo wezikhathi ezingu-5 ~ 7 zokusetshenziswa kwempahla ngehora ku-crystallizer & hopper. |

| Ukusebenza | Kulula--- Ngokulawulwa kwe-Siemens PLC

| Kunzima njengokuthi kufanele ifake i-PET encane ecwebezelayo ku-crystallizer lapho iqala ukusebenza. |

| Isondlo | 1. Elula. 2. Izindleko zokunakekela eziphansi. | 1. Kunzima. 2. Izindleko zokunakekela eziphakeme. |

Izithombe Zomshini

Ukuhlola Okubalulekile Kwamahhala

Unjiniyela onolwazi uzokwenza ukuhlolwa. Abasebenzi bakho bamenywa ngokufudumele ukuthi babambe iqhaza emizileni yethu ehlanganyelwe. Ngakho unakho kokubili ithuba lokunikela ngenkuthalo kanye nethuba lokubona imikhiqizo yethu isebenza.

Ukufakwa komshini

>> Nikeza unjiniyela onolwazi efekthrini yakho ukusiza ukufakwa kanye nokuhlolwa kwempahla kusebenza

>> Yamukela ipulaki yendiza, asikho isidingo sokuxhuma izintambo zikagesi kuyilapho ikhasimende lithola umshini efektri yalo. Ukwenza lula isinyathelo sokufaka

>> Nikeza ividiyo yokusebenza ukuze ifakwe kanye nomhlahlandlela osebenzayo

>> Ukwesekwa on line service