I-PET Bottle Flake Granulation Line

I-PET Bottle Recycling Pelletizer PET Granulation Machine Process flow

Isiphakeli se-vacuum → Isomisi sekristalu esingaboli → I-vacuum dis-charger → Isikulufu esisiqhafaza esisodwa →Isishintshi sesikrini se-hydraulic → Ikhanda elipholisa amanzi elipholisa amanzi →Isitsha sokugezwa samanzi → I-pelletizer ecwebezelayo → Umshini wokuwakhipha amanzi→Umshini wokuhlunga odlidlizayo→Ukupakisha umkhiqizo oqediwe.

Ukucaciswa Kwezobuchwepheshe

|

Igama Lomshini |

I-PET Single Screw Extrusion pelletizing Line |

|

Impahla eluhlaza |

I-rPET Flakes |

|

Umkhiqizo wokugcina |

I-rPET Pellets |

|

Izingxenye Zomugqa Wokukhiqiza | Uhlelo lwe-infrared crystal dryer: I-vacuum feeder/ I-infrared crystal dryer/ Isikhiphi sevacuum

Umugqa we granulating we-Screw Extrusion owodwa: Isikulufu esisodwa esikhulu esikhipha isikrini/I-Hydraulic Double Pistons eshintsha isikrini/Ikhanda le-Die/Isitsha samanzi ahluzayo/I-pellitizer eshaywayo/Umshini wokukhipha amanzi ome mpo/Umshini wokusefa odlidlizayo/Isitoreji

|

|

Isikulufu ububanzi |

90mm-150mm |

|

L/D |

1:24/1:30 |

|

Ibanga lokuphumayo |

150-1000KG/H |

|

Isikulufu impahla |

38CrMoAlA nge-Nitrding Treatment |

|

Uhlobo lwePelletizing |

Ukugudluzwa kwamanzi kanye ne-pelletizing |

|

Ukushintsha isikrini |

I-Hydraulic Double Pistons Screen Changer |

Imininingwane Yomshini

I-Infrared Crystal Dryer (I-LIANDA PATENT DESIGN)

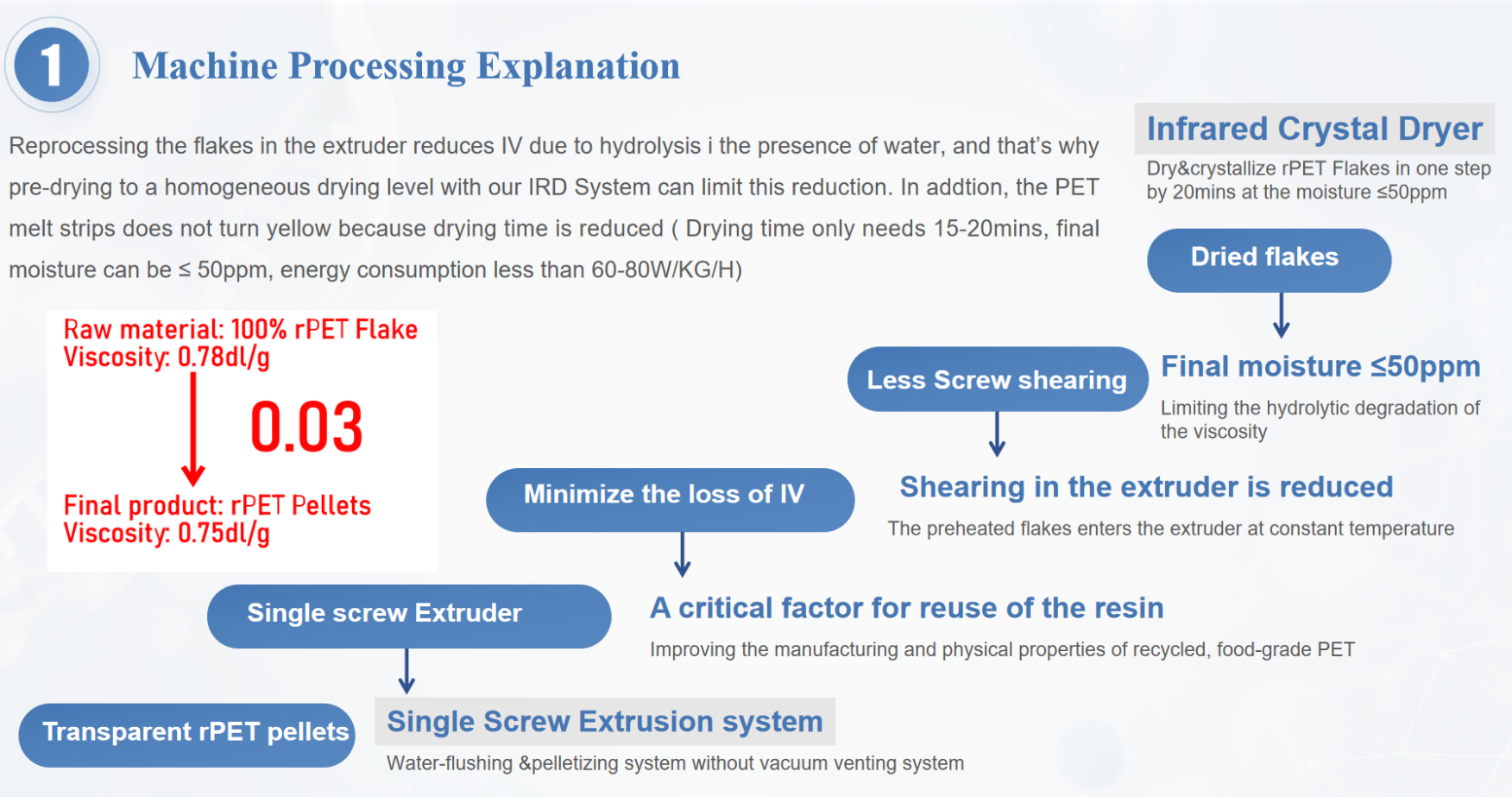

①Ukuthuthukisa ukukhiqizwa kanye nezakhiwo ezibonakalayo ze-PET egaywe kabusha, yebanga lokudla ngobuchwepheshe obunikwa amandla i-infrared wave kunengxenye ebalulekile okufanele iyidlale esakhiweni se-intrinsic viscosity (IV)

②Pre-crystallization & ukomiswa kwama-flakes ngaphambi kokukhishwa kusiza ukunciphisa ukulahlekelwa kwe-IV ku-PET, isici esibalulekile ekusetshenzisweni kabusha kwe-resin.

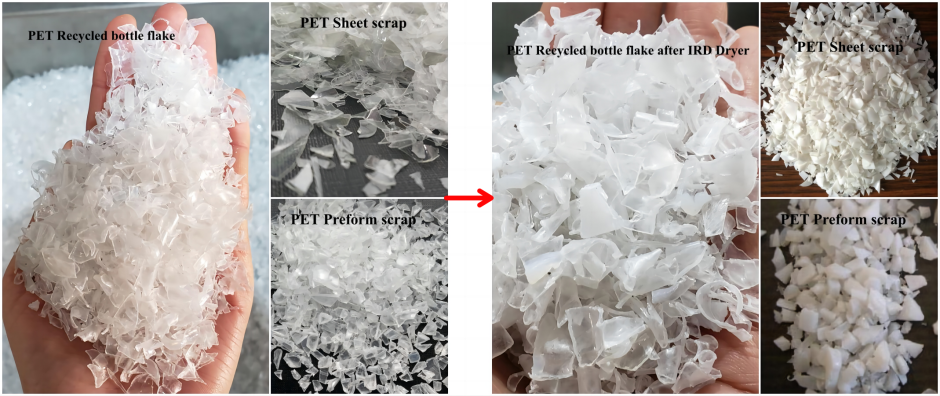

③Ukucubungula kabusha ama-flakes ku-extruder kunciphisa i-IV ngenxa ye-hydrolysis lapho kukhona amanzi, futhi yingakho ukomisa kusengaphambili ukuya ezingeni lokumisa elilinganayo ngohlelo lwethu lwe-IRD kungakhawulela lokhu kuncipha.

Ngaphezu kwalokho, i-PET melt strips ayiphuzi ngoba isikhathi sokumisa sincishisiwe (Isikhathi sokumisa sidinga kuphela i-15-20mins, umswakama wokugcina ungaba ≤ 30ppm, ukusetshenziswa kwamandla ngaphansi kuka-60-80W / KG / H)

④Ukugunda kwi-extruder nakho kuyancishiswa ngoba impahla eshisiwe ngaphambilini ingena ku-extruder ngezinga lokushisa elingashintshi”

⑤Ukuthuthukisa okukhiphayo kwe-PET Extruder

Ukwenyuka kokuminyana kwenqwaba ngo-10 kuya ku-20 % kungafinyelelwa ku-IRD, kuthuthukisa ukusebenza kokuphakelayo endaweni yokufaka i-extruder kakhulu - kuyilapho isivinini se-extruder sihlala singashintshile, kunokusebenza kokugcwalisa okuthuthuke kakhulu kusikulufu.

Ulayini Owodwa Wesikulufa Okhipha iPelletizing (Ngaphandle Kokuvula I-Vacuum)

Sisebenzisa amandla e-Single screw extruder futhi siyibhanqa ngesikulufu se-LIANDA esiklanywe ngendlela ehlukile sama-rPET Bottle flakes, sikwazile ukwandisa umthamo ngo-20% ngamandla amancane asetshenzisiwe uma kuqhathaniswa ne-Parallel double screw extruder.

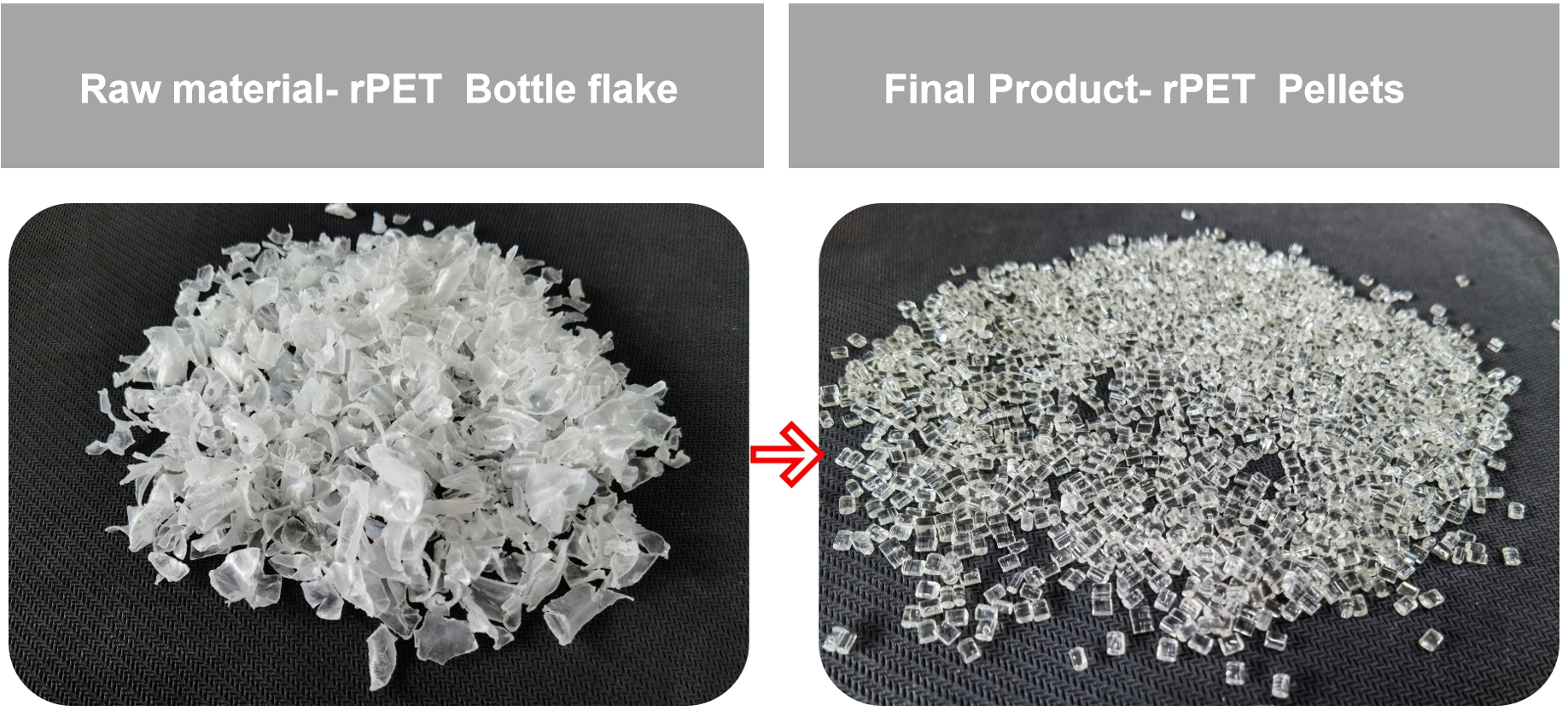

I-Viscosity yamapellets e-rPET akhiqizwa uhlelo lwethu: kukhona kuphela ≤0.02-0.03dl/g ukwehla kwe-viscosity ---ngaphandle kokwengeza noma yisiphi isithuthukisi se-viscosity. (Ngokwesivivinyo sethu sangaphakathi)

Umbala we-rPET pellets: obala --- ngaphandle kokwengeza noma yisiphi isithuthukisi obala

Ngaphandle kwesistimu yokungenisa umoya ngeVacuum --- Ukonga izindleko zamandla, ukusebenza okungenazinkinga nokusebenza okuzinzile

Izithombe Zomshini