Ifilimu ehlanganisa umugqa we-granulating

Isinyathelo esisodwa ubuchwepheshe for PP raffia, nokwelukiweyo kanye PE/PP Film udoti

I-granulator yokugaya kabusha ifilimu eklanywe i-LIANDA MACHINERY isebenzisa imodi yokukhiqiza yokuchoboza, i-hot-melt extrusion, i-pelletizing nokomisa, exazulula inkinga:

∎ Ubungozi bokondliwa ngezandla

■ Ikhono lokudla ngenkani lincane

■ Ukusetshenziswa okwenziwa ngesandla kokusebenza kokuhlukaniswa kokuchotshozwa nokukhipha kukhulu

■ Ubukhulu bezinhlayiyana zezintambo azifani, futhi izintambo ziphuka kalula

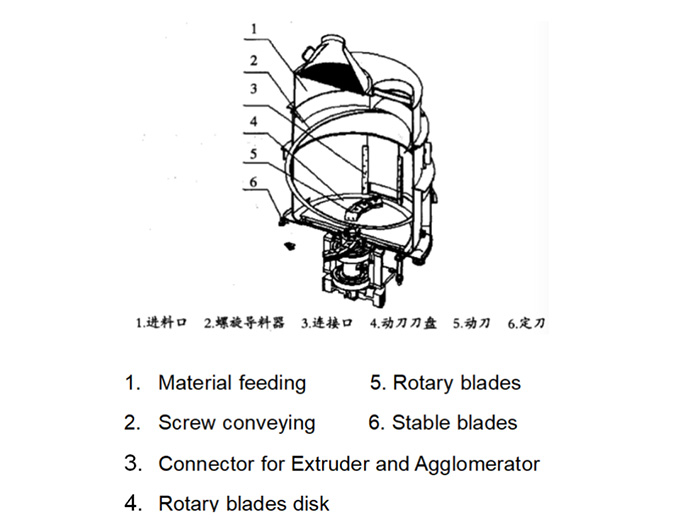

Imishini yokuhlanganisa ifilimu isebenzisa indlela yokuhlanganisa nokuchotshozwa. Ngemva kokuba impahla idliwe ku-compactor, izochotshozwa ngekhanda eliphansi lokusika, futhi ukungqubuzana okukhiqizwa ukusika kwekhanda lokusika ngesivinini esikhulu kudala ukushisa, ukuze impahla ishise futhi inciphe ukuze kwandiswe ukuminyana kwenqwaba. impahla futhi andise inani lokudla. Le ndlela yenqubo inosizo olukhulu lokwandisa umthamo wokukhiqiza

Imininingwane Yomshini

| Igama Lomshini | Ifilimu ehlanganisa umugqa we-granulating |

| Umkhiqizo wokugcina | Amapulangwe ePlastiki/granule |

| Izingxenye zomugqa wokukhiqiza | Ibhande le-conveyor, i-cutter compactor barrel, i-extruder, iyunithi ye-pelletizing, iyunithi yokupholisa amanzi, iyunithi yokomisa, ithangi lesilo |

| Indaba Yesicelo | HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

| Ukondla | Ibhande le-Conveyor (Ejwayelekile), I-Nip roll feeder (Ongakukhetha) |

| Isikulufu ububanzi | 65-180 mm |

| Isikulufu L/D | 30/1; 32/1;34/1;36/1 |

| Ibanga lokuphumayo | 100-1200kg/h |

| Isikulufu impahla | 38CrMoAlA |

| Ukukhipha umoya | Ukukhipha umoya okukodwa noma okukabili, Okungavezwanga ifilimu engaphrintiwe (eyenziwe ngokwezifiso) Uhlobo lwesiteji ezimbili (i-extruder yomama nengane) yokukhipha umoya ongcono nakakhulu |

| Ukusika uhlobo | Indandatho yamanzi iyasikwa noma ifa ngentambo |

| Ukushintsha isikrini | Isikhundla esiphindwe kabili sokushintshwa kwesikrini se-hydraulic esingami noma ngokwezifiso |

| Uhlobo lokupholisa | Amanzi apholile |

Imininingwane Yomshini Ibonisiwe

>> I-Film compactor/Agglomerator izosika ifilimu futhi ihlanganise ifilimu ngokungqubuzana kwesivinini esikhulu

>> I-Film compaction/ agglomerator yakhelwe ngefasitela lokubuka ukusiza amakhasimende ukuthi avule, ahlanze futhi ashintshe izindwani

>> Ngemva kokuba impahla ingene ku-compactor, iyachotshozwa futhi ihlanganiswe, futhi i-compactor ejikelezayo enesivinini esiphezulu iphonsa izinto ku-extruder-screw extruder eduze kwendlela yokugeleza. Ukushisa okuphezulu kungadalwa ku-compactor, ukuhlanganisa ipulasitiki kuma-pellets kanye

>> I-pelletizer yendandatho yamanzi, isivinini se-pelletizing silawulwa yi-inverter, okuhlanganisa ukufa kokusika okushisayo, i-diverter cone, isembozo sendandatho yamanzi, isibambi sommese, idiski yommese, ibha yommese njll.

>> Isiguquli sesikrini se-hydraulic esingami, kunenzwa yokucindezela ekhanda ukuze ushintshe isikrini, asikho isidingo sokuma ukuze kushintshwe isikrini, nokushintsha kwesikrini okusheshayo

>> Ama-pellets azosikwa ngokuqondile ekhanda le-water-ring die, futhi ama-pellets azophakelwa emshinini wokuqeda amanzi oqondile ngemva kokuba amanzi esepholile, inkinga yokuphuka kwemicu ngeke ibe khona;

Uhlelo Lokulawula

■ Ukondla: I-Conveyor yebhande iyasebenza noma cha incike emalini kagesi yeCompactor/Agglomerator kagesi. I-Belt conveyor izoyeka ukudlulisa kuyilapho amandla kagesi e-Film compactor/ agglomerator edlula inani elimisiwe.

■ Izinga lokushisa le-Film Compactor/Agglomerator: Izinga lokushisa elikhiqizwa ukungqubuzana kwempahla kufanele liqinisekise ukuthi impahla iyashisisa, igoqekile, igoqekile, futhi ingena ku-extruder ngokushelela, futhi inomthelela othize ejubaneni lokuzungezisa le-compactor motor.

■ Isivinini se-Screw extruder singalungiseka (Ngokusho ngokucaphuna kwezinto eziphakelwayo)

■ Ijubane le-pelletizing lingalungiseka (Ngokusho kokuphumayo nosayizi)