Isomisi sekristalu esingabonakali se-R-PET Pelletizing/ Extrusion Line

I-Infrared Pre-Drying of PET Flakes: Ukwandisa Okukhiphayo kanye Nokuthuthukisa Ikhwalithi Kuma-PET Extruder

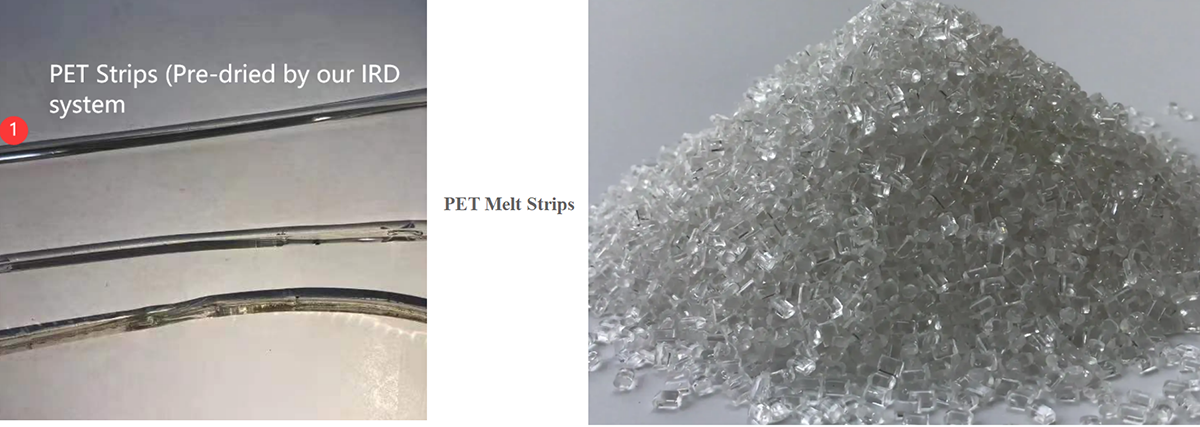

>> Ukucubungula kabusha ama-flakes ku-extruder kunciphisa i-IV ngenxa ye-hydrolysis i ukuba khona kwamanzi,futhi yingakho ukomisa kusengaphambili kuze kufike ezingeni lokumisa elilinganayo ngohlelo lwethu lwe-IRD kungakhawulela lokhu kuncipha. Ukwengeza, i-resin ayiphuzi ngoba isikhathi sokumisa sincishisiwe (Isikhathi sokumisa sidinga kuphela i-15-20mins, umswakama wokugcina ungaba≤ 50ppm, ukusetshenziswa kwamandla ngaphansi kuka-80W/KG/H), futhi ukugunda ku-extruder nakho kuyancishiswa ngoba impahla eshisiwe ingena ku-extruder ngokushisa okungashintshiyo”

>> Esinyathelweni sokuqala, i-PET regrind icwebezelwa futhi yomiswa ngaphakathi kwe-IRD phakathi nesikhathi esicishe sibe yimizuzu eyi-15. Le nqubo yokwenza amakristalu nokomisa ifinyelelwa ngenqubo yokushisa eqondile kusetshenziswa imisebe ye-infrared, ukufeza izinga lokushisa elingu-170˚C. Ngokuphambene nezinhlelo zomoya oshisayo ezihamba kancane, okokufaka kwamandla asheshayo naqondile kusiza ukulinganisa okuphelele kwamanani omswakama okokufaka ashintshashintshayo unomphela - uhlelo lokulawula lwemisebe ye-IR luvumela ukuphendula ezimweni zenqubo eziguquliwe ngemizuzwana. Ngale ndlela, amanani asukela phakathi kuka-5,000 kanye no-8,000 ppm ancishiswa ngokufanayo ngaphakathi kwe-IRD ukuya ezingeni lomswakamo eliyinsalela elingaba ngu-30-50ppm.

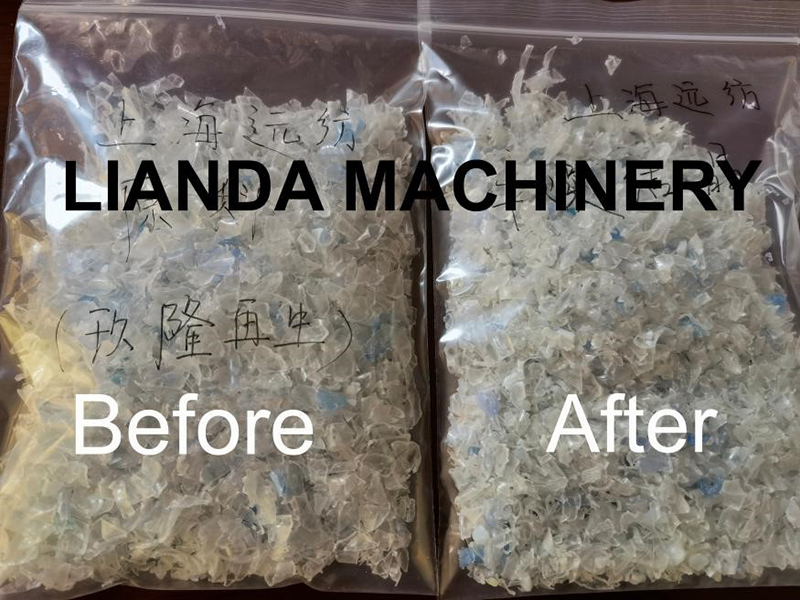

>>Njengomphumela wesibili wenqubo ye-crystallization ku-IRD, ukuminyana kwenqwaba yezinto zomhlabathi kuyanda,ikakhulukazi kuma-flakes anesisindo esincane kakhulu. Lo mphumela wesibili uthakazelisa kakhulu uma kuqhathaniswa nengemuva lokuthi ukuthambekela kumabhodlela anezindonga ezincane kuvimbela okokusebenza kabusha ekuzuzeni ukuminyana kwenqwaba > 0.3 kg/dm³. Ukwenyuka kokuminyana kwenqwaba ngo-10 kuya ku-20 % kungafinyelelwa ku-IRD, ebonakala ingabalulekile ekuqaleni, kodwa ithuthukisa ukusebenza kokuphakelayo endaweni yokufaka i-extruder kakhulu - kuyilapho isivinini se-extruder sihlala singashintshile, kukhona okuthuthuke kakhulu. ukugcwalisa ukusebenza kusikulufa.

Isikhathi sokuthumela: Apr-07-2023